Development and Production of Switch-Disconnector Testing Unit

Customer

ABB OY (Finland)

Completion Date:

01.08.2024

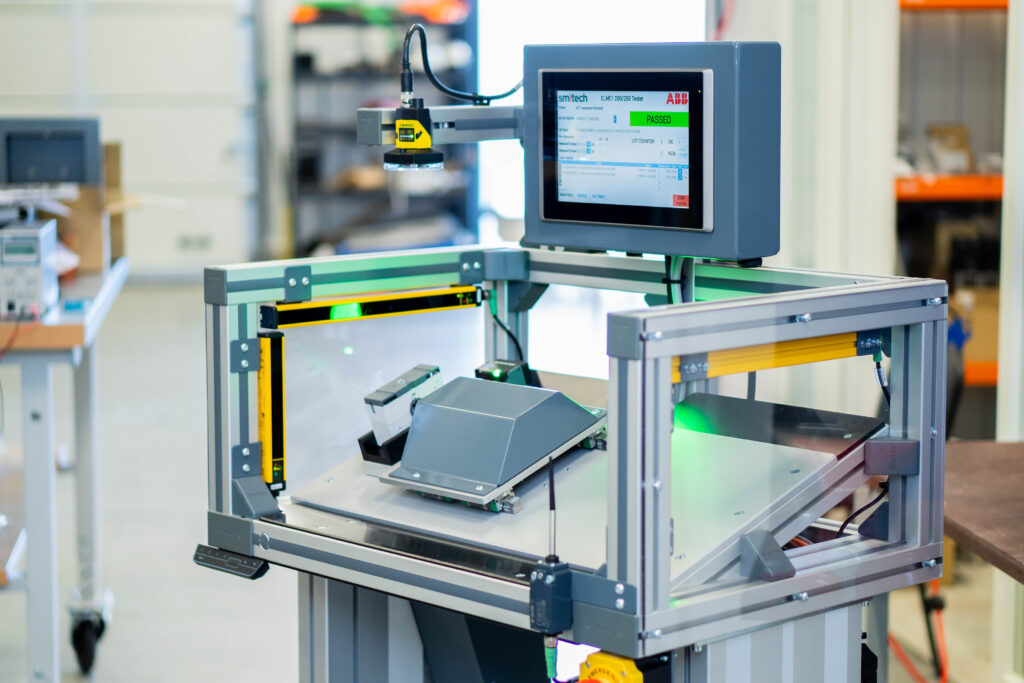

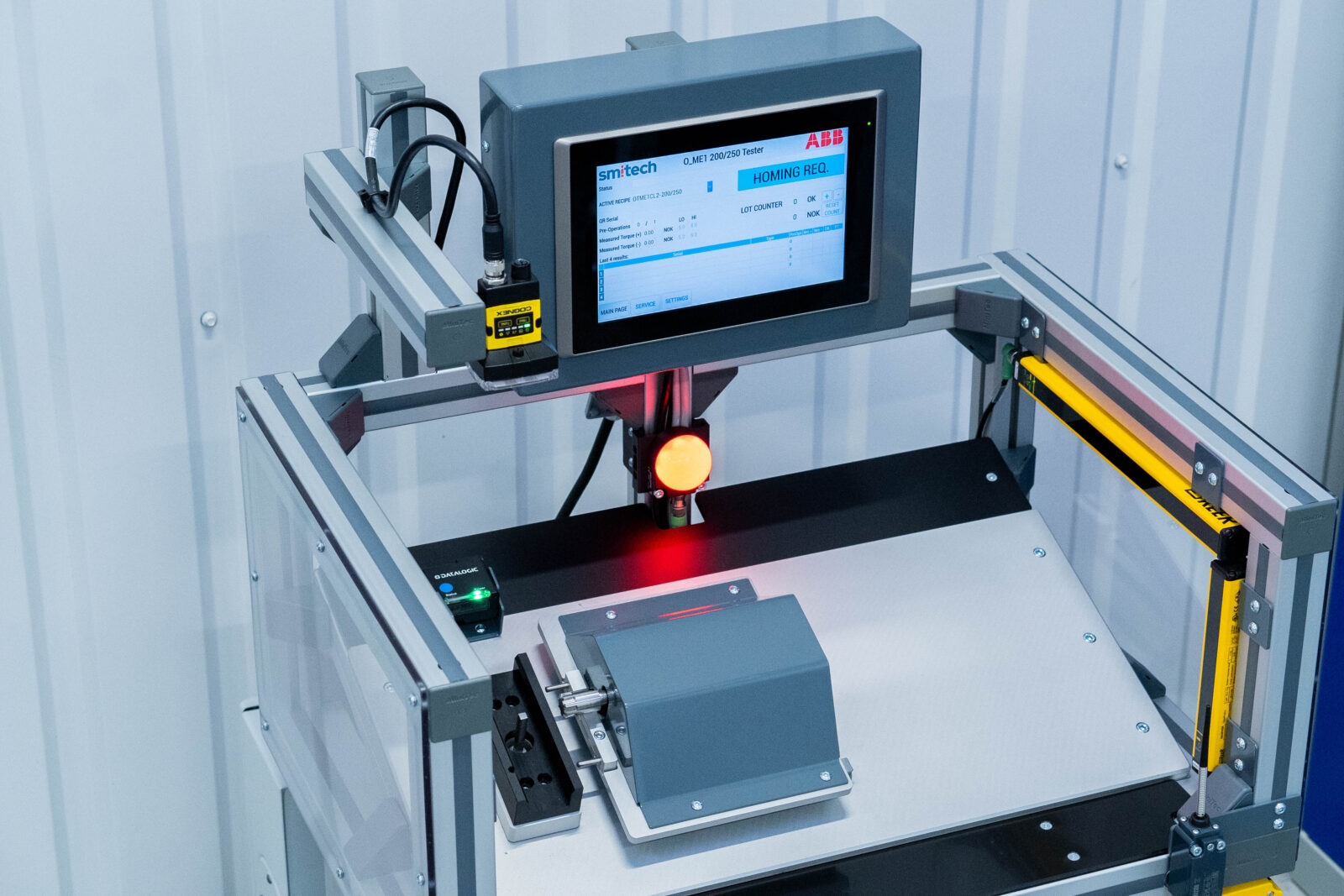

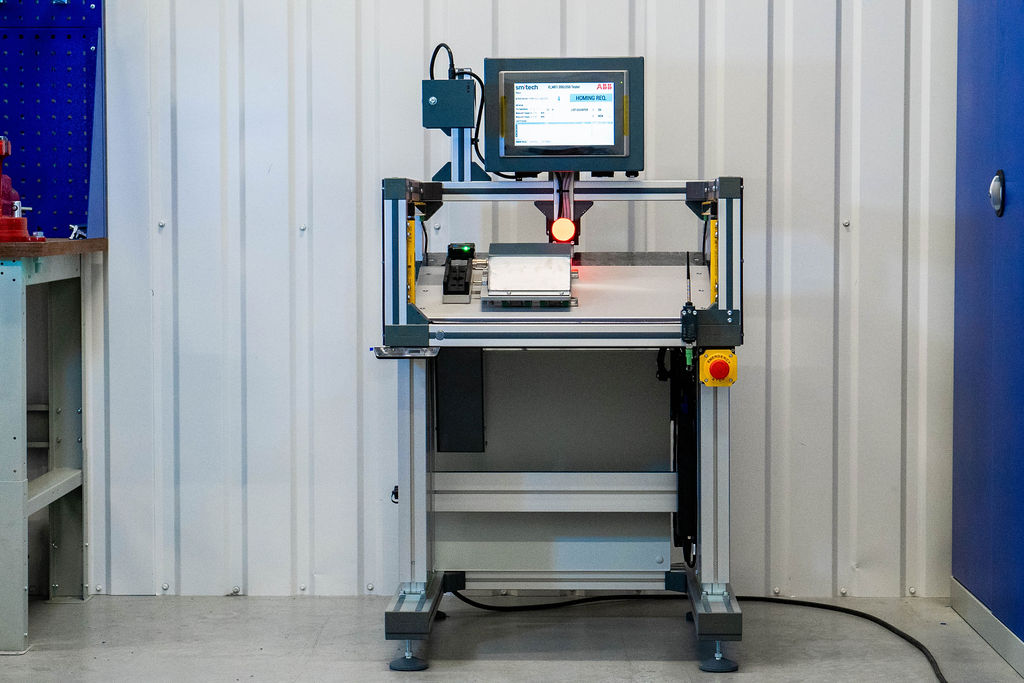

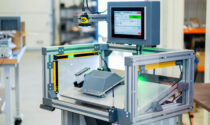

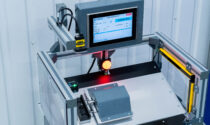

At the client’s request, we developed a new product functionality tester platform for a product series: switch-disconnectors. It is a modular platform used to test products of various sizes by simply changing the product fixture attached to the table.

In total, we developed and produced 5 testers for the client for testing products of different sizes within the same family.

Key functionalities of the testing system:

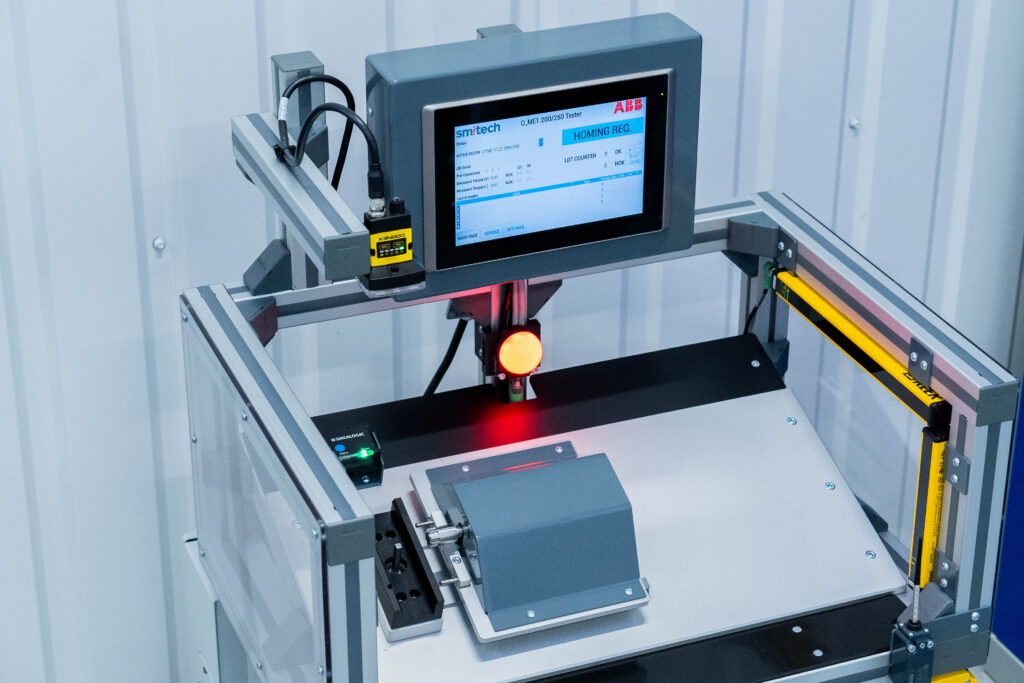

- Servo-driven product manipulation for performing various switching operations;

- Feedback from a force sensor to measure switching forces (up to 20 Nm), to verify the product’s compliance at the end of the production process;

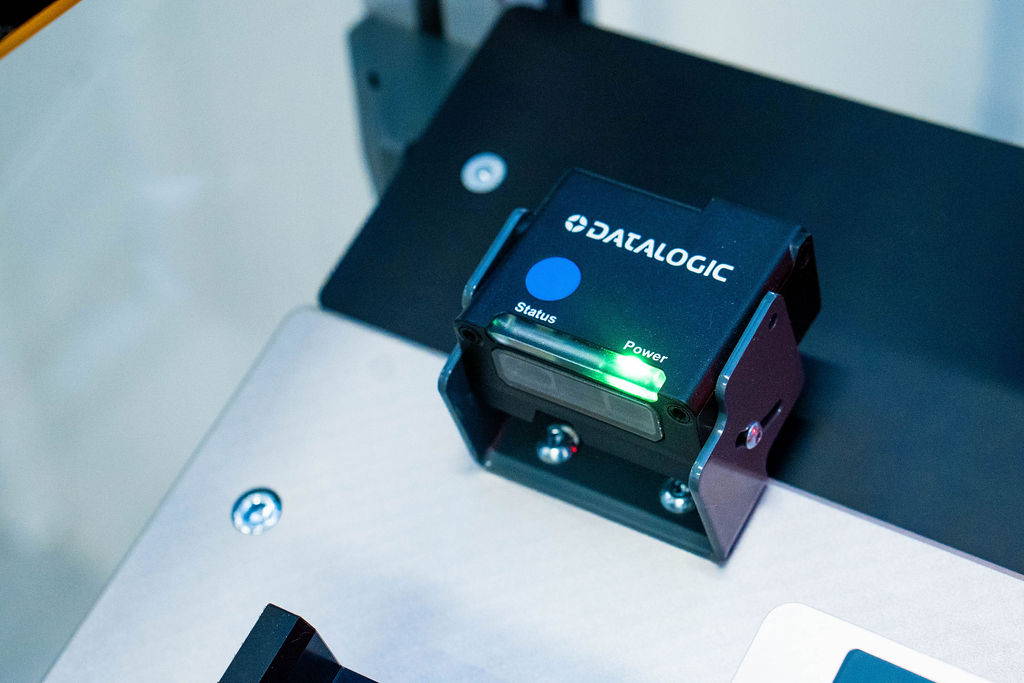

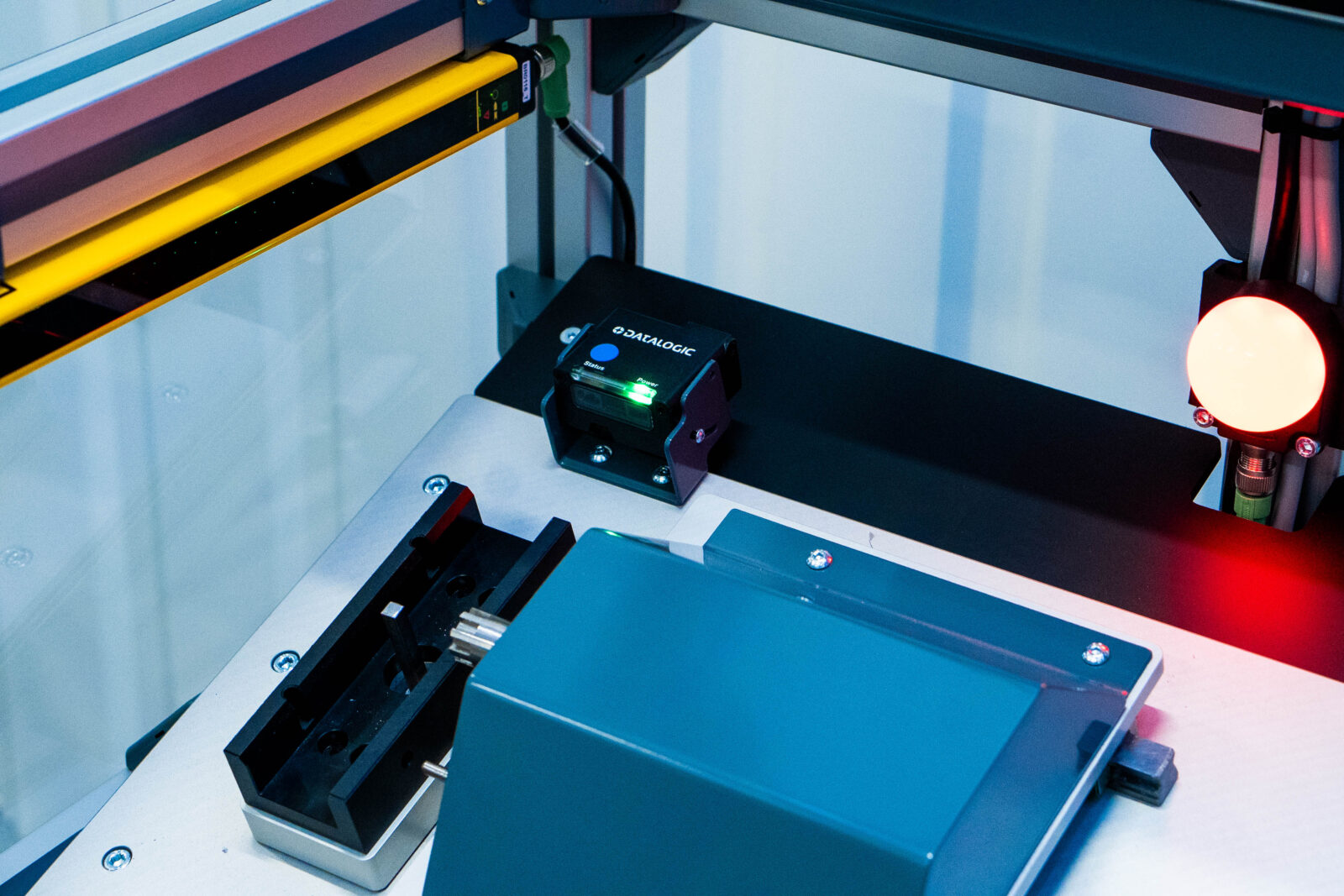

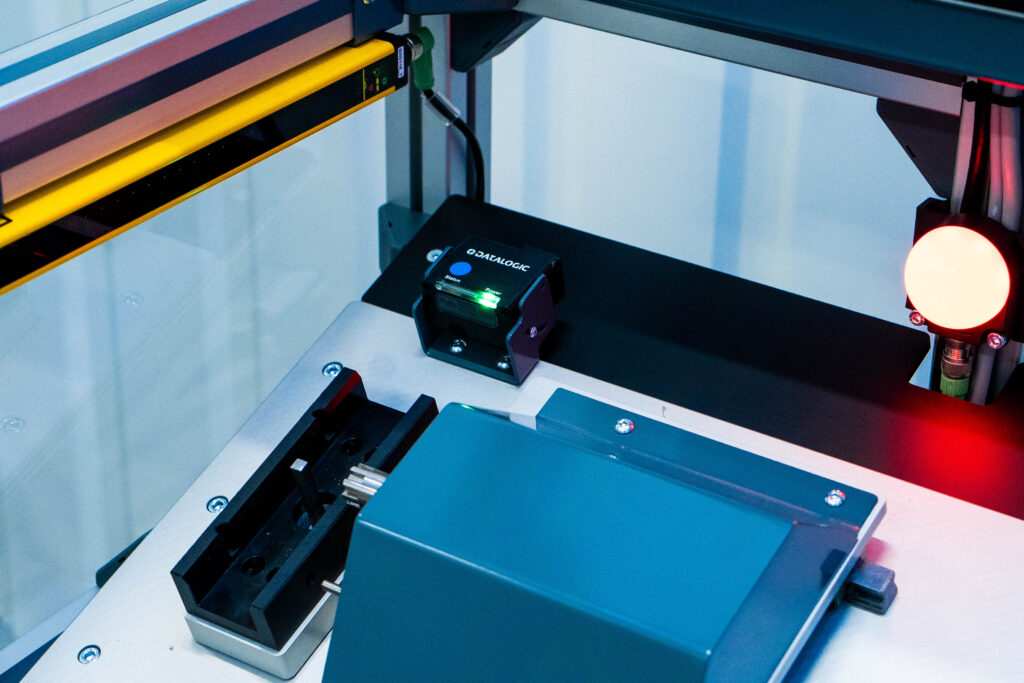

- QR code scanning from the product to ensure traceability and to switch recipes (different switching procedures are performed depending on the product);

- Logging of all tested products (in .csv format) and storing data (generation of a new .csv file once a day to ensure traceability);

- Machine vision control to check the mechanism’s functionality;

- “Golden Sample” procedure for validating the tester;

- For ergonomic purposes, the tester is built on a height-adjustable workbench.

The project included the following:

- Development of the tester platform in collaboration with the client;

- Development and design of mechanical systems;

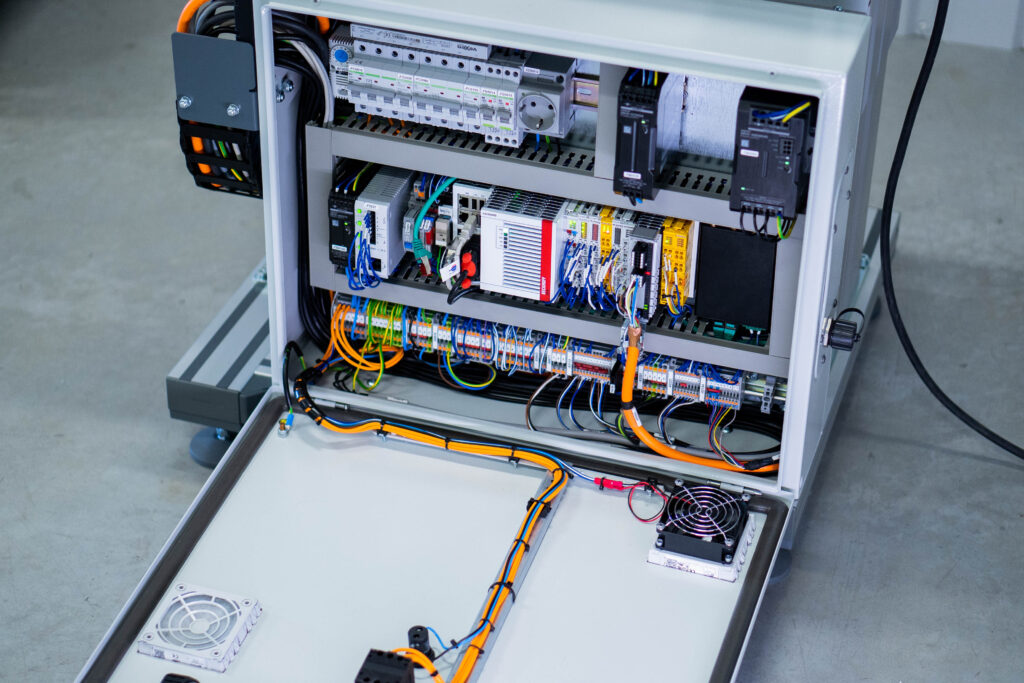

- Development and design of electrical and automation systems for the device;

- Manufacturing and assembly of the mechanical systems of the device;

- Assembly and construction of electrical and automation systems for the production line;

- Design and production of the electrical cabinet;

- Full development of the control system, PLC programming;

- CE certification (risk analysis, compliance assessment).

Hardware used:

- All automation is based on the Beckhoff control system;

- Beckhoff servo motor for performing tests;

- Datalogic scanners for reading product QR codes;

- Cognex camera system for mechanism validation.