Machine Build

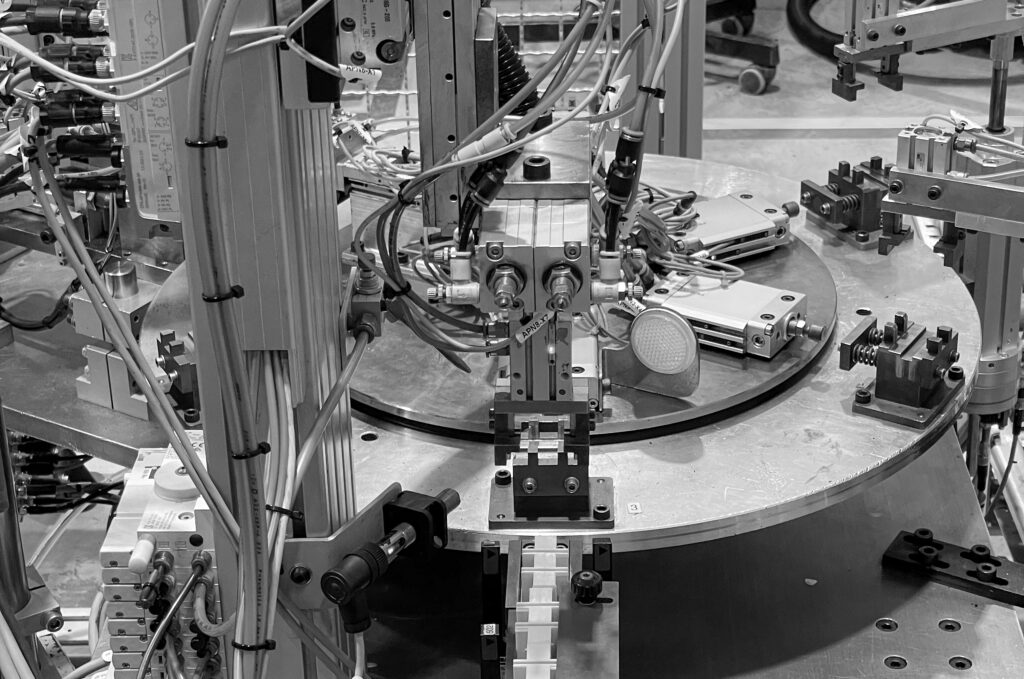

SMITECH OÜ offers manufacturing and industrial equipment production services.

Our core capability lies in engineering project management – we manage the entire process from component sourcing to equipment commissioning. We are a reliable and trustworthy partner for our customers, since we have the competence to have a say in the development of the whole concept from the very beginning of the development phase – this way the end customer gets a production line and/or an industrial device which is reliable and safe.

We offer our customers a comprehensive mechanical engineering service:

- Project management

- Sourcing and manufacturing of components

- Assembly of the device

- Commissioning and testing of the device

- Installation works

- After-sales maintenance and technical support

If necessary, we also have the ability to help with product development in the design of mechanical, electrical and automation systems.