We map the production process and, since the experience of employees involved in a specific production stage is also important to us, we also interview them if necessary.

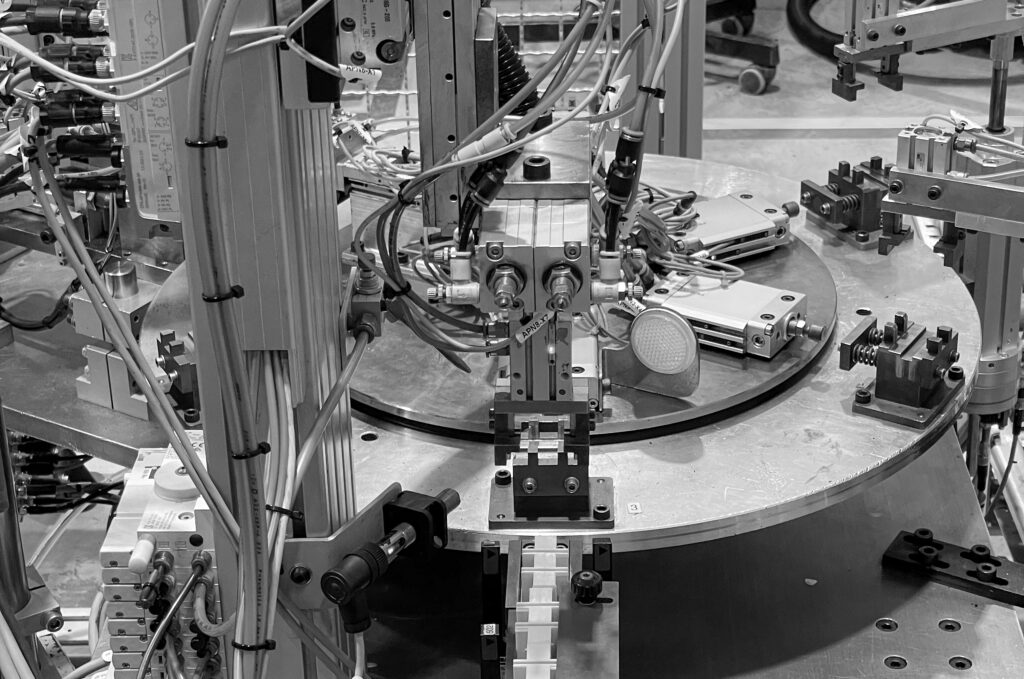

Then we set priorities. We set metrics. We choose the right technology and assembly components.

Since proper preliminary work and accurate calculations are the lion’s share of the project’s success, we are very thorough. This is how the initial task of the production automation project is born. Already here, we take into account that the time when we install the automation system would be as convenient as possible, considering the customer’s production process.