INDUSTRIAL ROBOT SYSTEM FOR 1000T PRESS TENDING

Customer: Metec Group

Project end date: 01.03.2025

Application: 1000T press tending robot

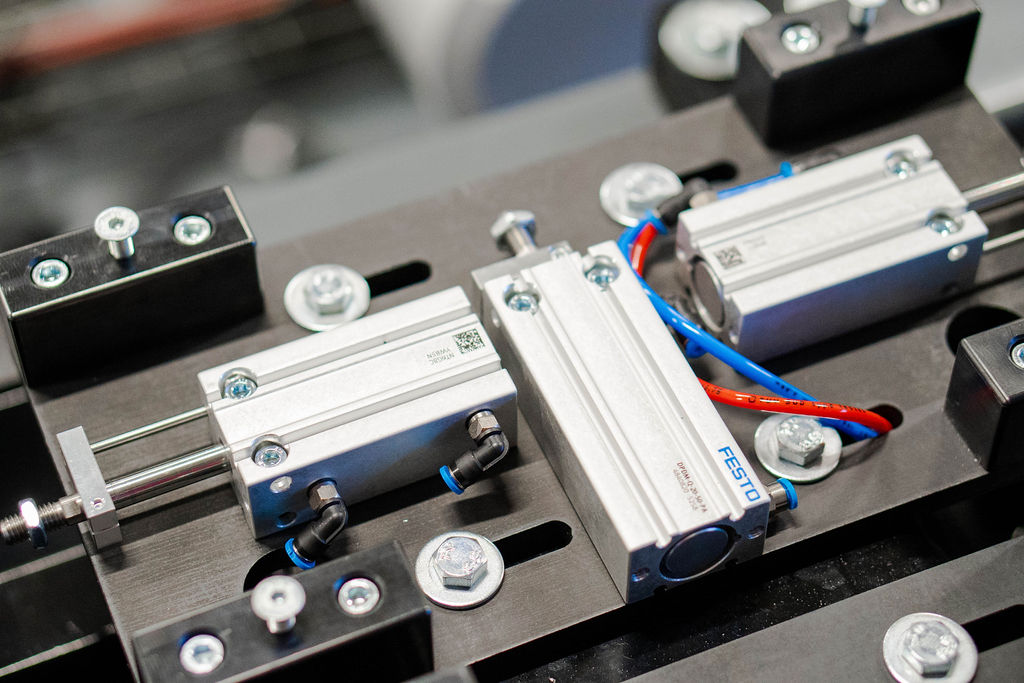

Solution: We developed and manufactured a highly automated 1000T press die feeding system for Metec Group using ABB industrial robots. We also designed a mechanism for feeding products in and out of the die.

Objective: To create a robot solution dedicated to servicing a specific press die, which can be easily removed from the press at any time and effortlessly reinstalled by the operator. The goal of automation was to eliminate one manual labor position, increase productivity, and automate quality control.

Technical Specifications:

- Industrial robots: ABB (2pcs) with synchronous movements;

- Control system: 100% automated product measurement system using a 3D scanner (Cognex);

- Safety solutions: The safety system uses a LiDAR system, which creates a safety zone around the device without fixed physical elements;

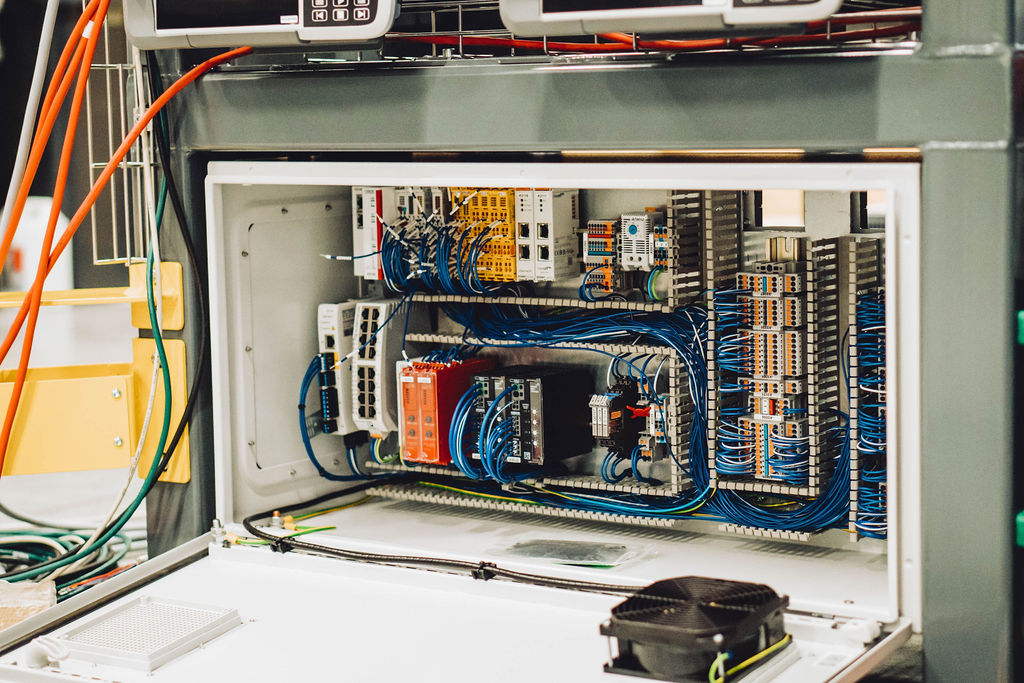

- Control systems: A solution developed using the Beckhoff PLC system. OPC/UA interface for connecting to the company network (data transmission to the system).

Functionality:

- The system can be moved away from the press to allow for various other operations with dies that are not automated.

- A fast work cycle of 12.5 seconds per product ensures high productivity.

- An ABB industrial robot capable of picking up products from a Euro pallet and placing them onto Euro pallets without using machine vision systems. Two Industrial Robots to perform synchronized movements;

- 3D scanner for product quality inspection (geometrical measurements);

- OPC/UA connection for data handling.

Work performed within the project:

- Design and development of mechanical, electrical, and automation systems.

- Design and installation of safety systems.

- PLC Programming, Vision System Programming

- Manufacturing of the equipment and installation at the client’s production facility.

- CE certification, including risk analysis and compliance assessment.